Overview

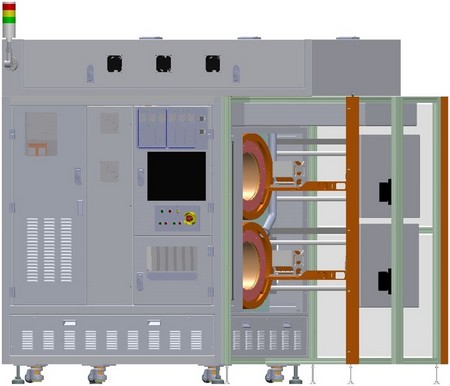

The Load Lock Chamber serves as a buffer module that transitions pressure between atmospheric and vacuum states, positioned between the vacuum and ambient chambers.

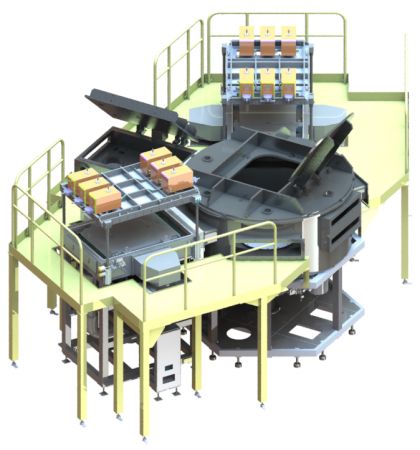

The Cluster Transfer Module transports glass substrates from the load lock to the process chamber with precision and reliability.

Specifications

- Glass Size Compatibility: 4G ~ 8G

- Wafer Size Compatibility: 4" ~ 12"

- Vacuum Rate: 5 × 10-7 torr

- Material: Aluminum or Stainless Steel (STS)