The heating jacket is also known as heater jacket, heat jacket, or jacket heater, but our company refers to it as Heating Jacket.

The heating jacket helps reduce human, material, and economic losses caused by powder accumulation in gas exhaust pipes during semiconductor and other manufacturing processes, which can lead to equipment performance degradation, reduced production yield, and periodic preventive maintenance.

Our product is CE certified, made from special high-temperature resistant raw materials, and includes various safety devices to ensure safe use and excellent performance.

Applicable processes or products include:

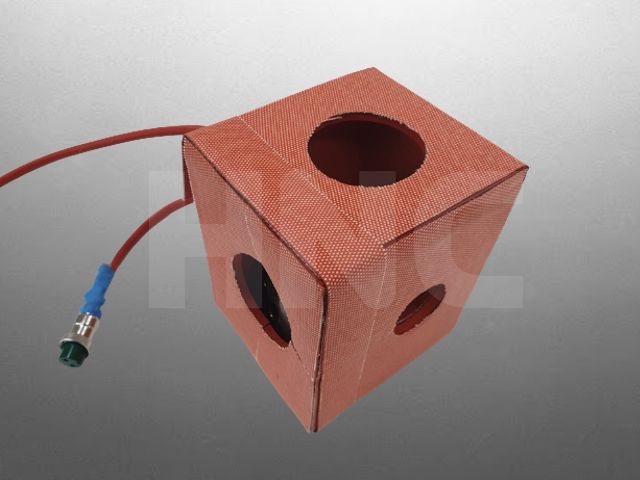

Various Forms

Various Forms

Lightweight

Lightweight

Excellent Adhesion

Excellent Adhesion

Ensured Safety

Ensured Safety

Raw and Auxiliary Materials

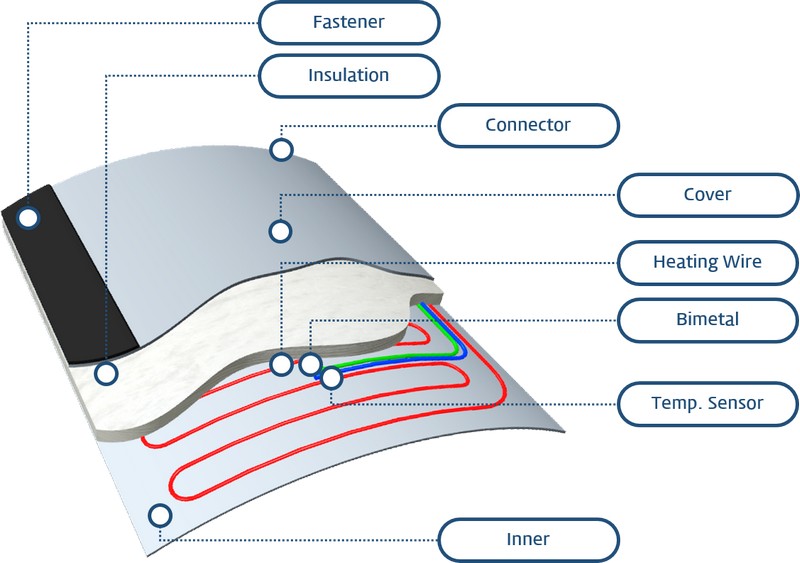

Raw materials (inner lining, outer lining, insulation, etc.) and auxiliary materials (fasteners, connectors, cables, etc.)

Raw and Auxiliary Materials

Raw materials (inner lining, outer lining, insulation, etc.) and auxiliary materials (fasteners, connectors, cables, etc.)

Design & Cutting

Materials are designed according to equipment blueprints and cut automatically.

Design & Cutting

Materials are designed according to equipment blueprints and cut automatically.

Sewing (Assembly)

Inner lining (heating wires), insulation, and outer lining are sewn, followed by assembly of connectors and fasteners.

Sewing (Assembly)

Inner lining (heating wires), insulation, and outer lining are sewn, followed by assembly of connectors and fasteners.

Testing

Insulation resistance and dielectric strength are measured, and out-gassing is checked through aging tests.

Testing

Insulation resistance and dielectric strength are measured, and out-gassing is checked through aging tests.

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Order Type

Fabric Elbow Straight Type

Fabric Elbow Straight Type

Fabric Straight Type

Fabric Straight Type

Fabric Order Type

Fabric Order Type

Rubber Straight Type

Rubber Straight Type

Rubber Elbow Straight Type

Rubber Elbow Straight Type

Rubber Valve Type

Rubber Valve Type

| No | Items | Fabric Type | Rubber Type |

|---|---|---|---|

| 1 | Temperature | 120~180℃(최대 250℃) | 120~180℃(최대 250℃) |

| 2 | Voltage | 220VAC(50/60Hz) | 220VAC(50/60Hz) |

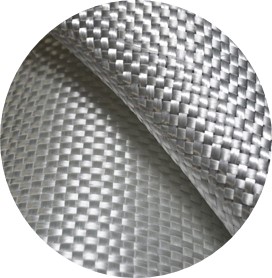

| 3 | Outter | Silicone coated E-glass cloth PTFE coated E-glass cloth Silica cloth, PTFE cloth Dual mirror aluminized cloth |

Silicone rubber fabric |

| 4 | Inner | Silicone coated E-glass cloth PTFE coated E-glass cloth Silica cloth |

Silicone rubber fabric |

| 5 | Insulation | Silica needle mat Fiber galss |

Silicone sponge Silicone pad |

| 6 | Heat Wire | Nickel-chrome wire(NCHW-1) | Nickel-chrome wire(NCHW-1) |

| 7 | Inter-lock(option) | Bimetal, Thermal Fuse | Bimetal, Thermal Fuse |

| 8 | Sensor | K-type, PT100Ω-type | K-type, PT100Ω-type |

| 9 | Fastener | Velcro, Snap Button | Snap Button |